Sustainability

Sustainability Impact – Best Practice in Rubber Recycling

Ecosystem

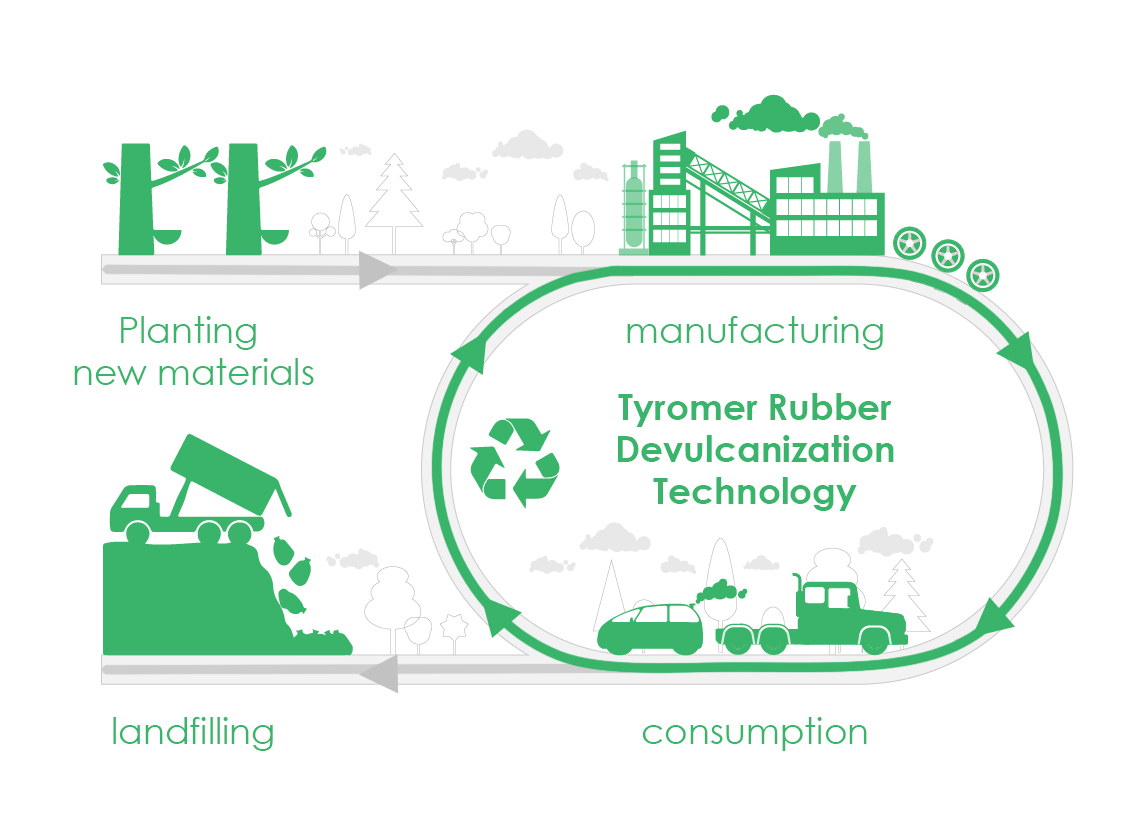

Each year more than 2 billion scrap tires are produced globally. During the average life of a tire, only 20% of the rubber is used, leaving a staggering number with nowhere to go. Since there are limited uses for scrap tires, we burn nearly half of them for their fuel value. Besides posing environmental air quality hazards, burning only recovers a small portion of the energy that went into making these tires’ rubber.

But for Tyromer, these end-of-life tires are really a renewable resource. Now with our environmentally-friendly rubber devulcanization technology, scrap tire rubber can be recycled into a new, versatile, high quality rubber master-batch material – Tire-Derived Polymer, or TDP that can used in making tires.

Unlike most reclaimed rubbers, Tyromer’s process does not use any devulcanization chemicals. In fact, there are no additives at all and the process is energy efficient.

Tyromer is nearing completion on a 3rd party Life Cycle Analysis (LCA) which will be available soon.

Environment and economic benefits

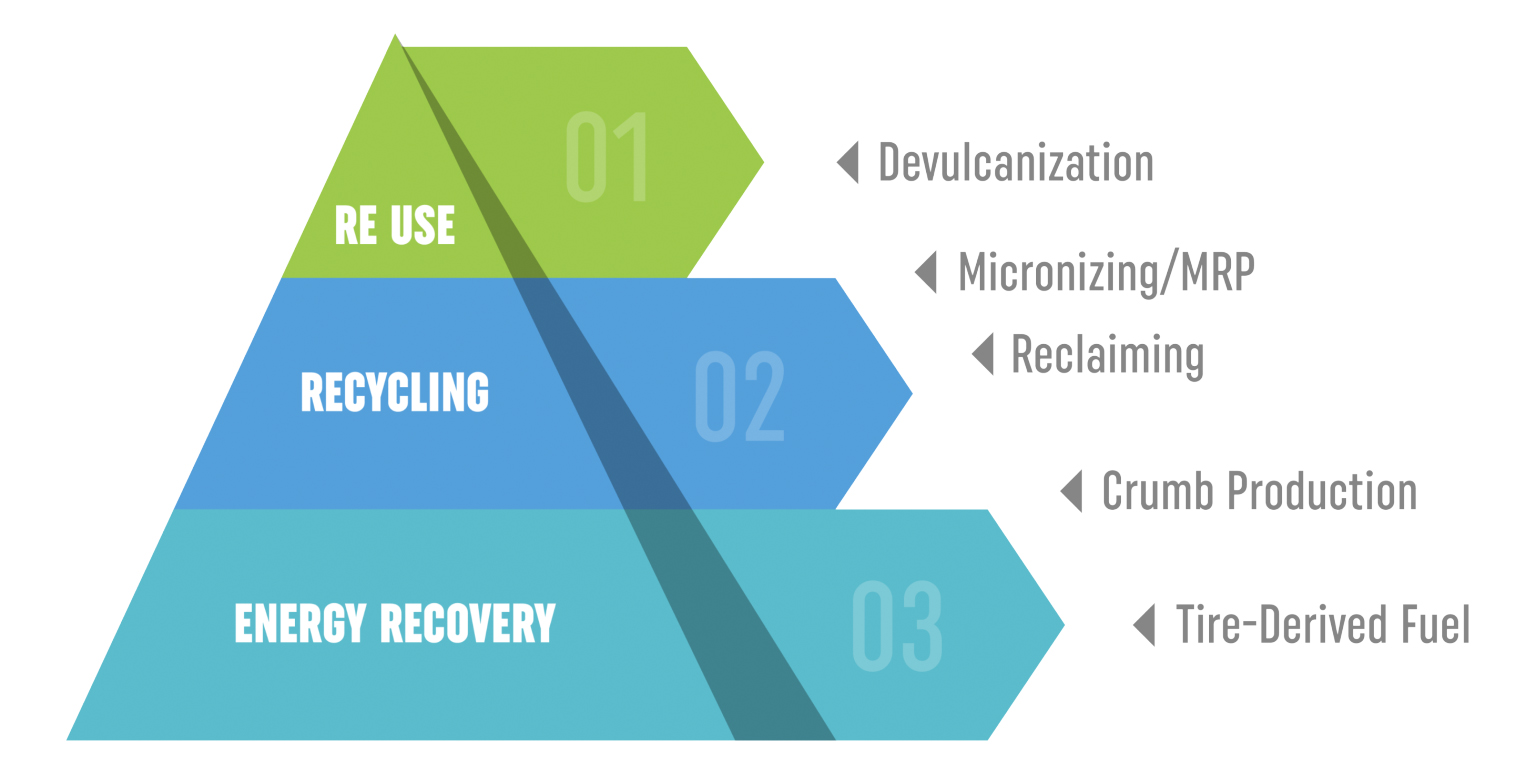

In the process of seeking sustainable solutions for waste tires and a circular economy, there are two other technologies besides devulcanization.

Micronization: cryogenically grind rubber into a very fine powder MRP in the size range of 80-120 mesh (China uses 40 mesh to produce reclaimed rubber), it is energy intensive and costly. As adding MRP will increase the compound viscosity very significantly, also the product is non- elastomeric can only be used as fillers, higher level of use is unlikely.

Pyrolysis: heat the scrap tire to high temperature and decompose it to obtain oil, carbon black (CB) and steel. Except for steel, the quality of other products is low and unstable, end products have limited market and limited use. In addition, the product flow of Pyrolysis is complex, it will cause harm to the environment in the event of incomplete thermal cracking, or high oxygen inflow, or improper disposal of dangerous products.

Today, close to 50% of global scrap / end-of-life tires are used as Tire-Derived Fuel (TDF) for energy recovery via incineration. As illustrated in the Recycling Pyramid, energy recovery is the lowest form of recycling. Because our TDP can be reused for its originally intended purpose, it represents the highest form of recycling.

While use of Micronized Rubber Powder (MRP) is also high on the pyramid, devulcanized material is able to be loaded in higher amounts compared to MRP in tires.Tyromer devulcanization technology will enable tire and rubber goods manufacturers to further reduce their carbon footprints, brings higher environmental and economic benefits.

Energy recovered from incineration of TDF

Energy conserved from using TDP in tires (compared to new tire compound)

Tyromer means:

Reduced consumption of synthetic rubber

a non-renewable petroleum-based resource

Reduced air pollution

more than half of all scrap tires are burned for their fuel value.

Reduced Greenhouse Gas

the use of TDP will reduces carbon emissions from making new tire rubber

Reduced environmental hazards

scrap tires devulcanization will minimax landfills and associate hazards

Innovation Continuation

- The research group of Professor Tzoganakis the technology inventor serves as an excellent HR pipeline to support growth

- The partnership with the University of Waterloo in Canada and the University of Twente, known as the “Rubber University” in Europe provides Tyromer access to large R&D infrastructure to support its global collaboration

- The cooperation with tire industry leaders gives Tyromer a front row seat in tire industry requirement and trends, to maintain its technological advantages and provide the most valuable services to the tire industry